Textile winding

Traditional textile winding

What is textile windinp

The objective of textile winding is to bring together the threads that have been previously formed in the spinning process, depending on which type of thread it is, it will be made with some tensions or with others, always taking into account the resistance capacity of the threads so as not to end up breaking it or fraying it.

Once the created thread is obtained, it must be conditioned and for this, 4 types of conditioning are carried out, the winding being one of them favoring the subsequent process, the phases prior to weaving.

Thread winding is usually done for threads that are used as filler threads or weft threads (threads that run across the fabric).

Types of textile winding

- Handbook

- twist the fibers by hand

- Industrial

The process to manufacture yarn begins in machines called "combers" that precisely have that function, combing the fiber by means of needles; Afterwards, the fiber passes through a mechanism called a scrubber, where the fiber is stretched and rolled into tubes to go on to the next process in the continuous ones where, by means of rollers and rings, the fiber is twisted to make it a thread; later it goes to the twisting section where two or more strands are joined.

Mechanical spinning machine

The mechanical spinning wheel is operated by hand or by repeatedly depressing a foot pedal. In doing so he spins the lathe and twists the wool as it winds it onto the spindle. A belt goes through a wheel and a small pulley to turn the lathe. Spinning lathes are much faster than hand spindles, but the spinner can only spin one size of yarn at a time.

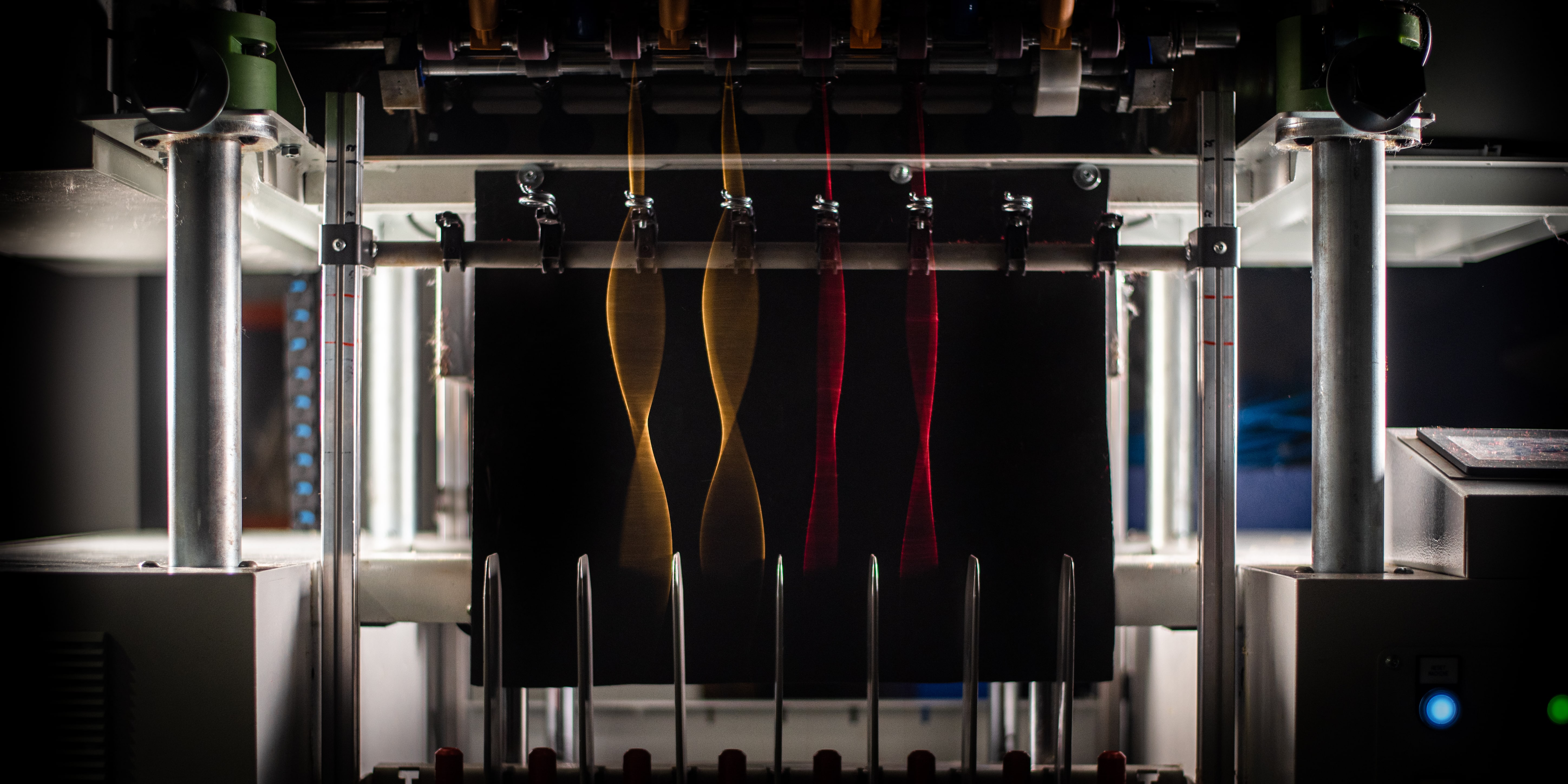

Revolution in textile winding

After many years spinning in the same way, spinhole has developed a textile winding that is much faster and more sustainable for the environment, readjusting the process and revolutionizing this industry.

Textile winding by country

The main manufacturing countries are China, India, the United States, Turkey, the Republic of Korea, Vietnam, Pakistan ...